Double Block AND Bleed valve

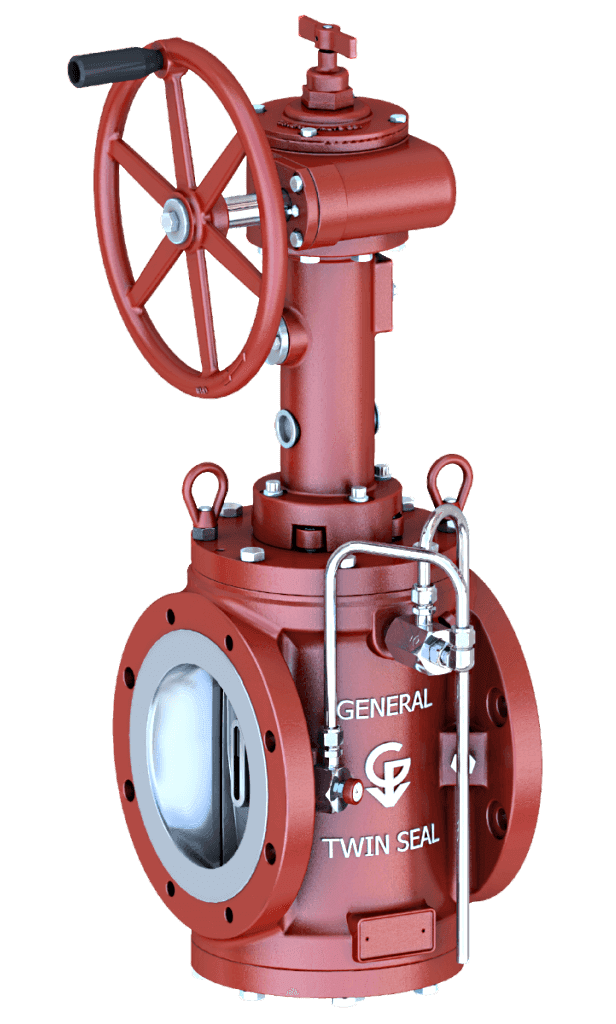

GENERAL TWIN SEAL valve

Stock available today in 2″ – 36″, ANSI 150# – 900#

The Largest Double Block and Bleed Valve Inventory in the world

Massive Parts Inventory Available for Overnight Delivery

- Extensions

- Electric Actuation

- Custom Coatings

Introduced in 1941, GENERAL VALVE Twin Seal plug valves, also known as Double Block and Bleed Valves, were the first to meet the rigid requirements of double block-and-bleed service. In the years since, subtle yet significant design refinements have further improved valve performance. Superior design innovations, pride in manufacturing workmanship, and selection of the best materials support our commitment to excellence and customer satisfaction.

Zero-Leakage Double Block-and-Bleed Plug Valve with Retracting Seals

In meter block service, the differential pressure across each closed valve is very low. No assistance is required from the line pressure to energize or compress floating seals to make them hold tight. The seals typically rely on springs to press them against the ball unless the body cavity in a ball valve is vented. The ball valve may be leaking until the user opens the bleed. Then, the reduction of the body pressure introduces a hydraulic force on the seat that may stop the leak. The user can form a false impression that the ball valve is holding tight, when in reality, it leaks. In contrast, the mechanical wedge action of the valve plug compresses both the upstream and the downstream seals firmly against the valve body, needing no help from the line pressure.