Orbit Rising Stem Ball valves for Molecular Sieve Dryers

Low-maintenance, high-integrity, zero-leakage solutions

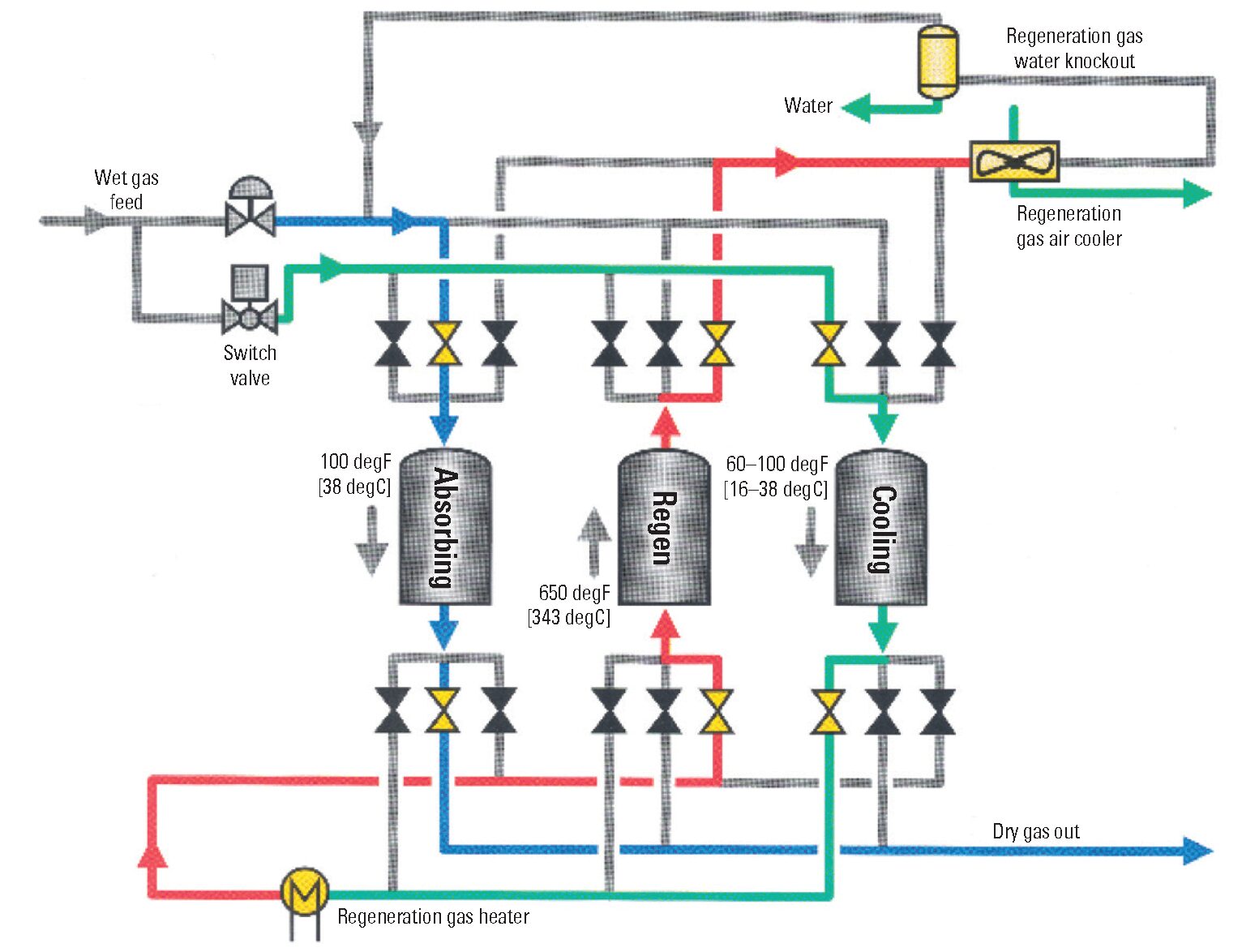

Schematic

Molecular sieve dryer system using ORBIT valves

Typical Challenge

Wet gas leaking through ordinary valves will cause dryer efficiency to decline.

Typical Challenge

ORBIT valves are cammed positively closed, eliminating wet gas leakage.

Typical Challenge

Leaking valves can prolong the regeneration time and waste energy.

Typical Challenge

The ORBIT valve design eliminates rubbing between seat sealing surfaces, ensuring zero leakage and conserving energy.

Typical Challenge

Daily operation in hot, abrasive service can create high maintenance costs.

Typical Challenge

ORBIT valves provide reliable long life in hot, abrasive service with reduced maintenance.

When ordering, specify ORBIT rising stem ball valves for molecular sieve service